Every piece of modern technology, from simple electrical circuits to large-scale servers, generates heat as it runs. If that heat isn’t controlled, it reduces efficiency, causes components to fail, shortens equipment lifespan, and increases power consumption.

For businesses, effective cooling is not optional; it’s what separates smooth daily operations from sudden downtime that can grind productivity to a halt. Cooling systems protect investments, preserve data integrity, and keep energy balanced across systems.

In industries where uptime directly impacts revenue and safety, reliable cooling becomes the backbone of operations, ensuring both technology and the people who rely on it can perform without disruption.

Air Conditioning for Electrical Rooms

Standard air conditioning remains one of the simplest yet most reliable solutions for protecting electrical equipment. In electrical rooms and smaller server spaces, dedicated AC units run continuously to maintain steady airflow and stable temperatures.

Unlike general building HVAC systems, these are built for nonstop operation, ensuring sudden temperature spikes don’t occur. Electricians often customize these installations to account for the heat load and ventilation requirements of the specific room.\

With consistent cooling in place, sensitive circuits, switchgear, and small-scale servers avoid the stress of overheating. This approach not only safeguards equipment but also reduces the risk of unplanned outages that can ripple across operations.

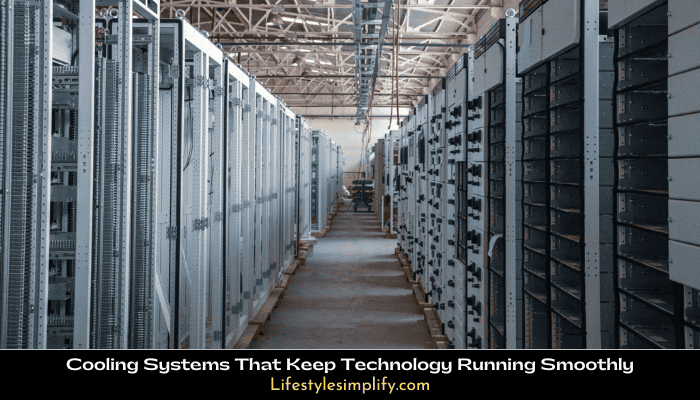

Cooling for Data Centers

ou can call data center the backbone of our digital world, whether it is for business, social or any other kind of information that has been stored online.

These center demand a special type of cooling system that helps them without any interruption, because an outage triggered by the failure of data center’s cooling system can cause millions of dollars lost in business.

Unlike standard AC, precision cooling systems manage temperature, humidity, and airflow with extreme accuracy, protecting servers from even minor fluctuations that could lead to downtime or hardware damage.

These facilities often employ layered strategies, including hot aisle/cold aisle containment, redundant cooling units, and integration with emergency power systems to maintain continuous operation.

In mission-critical environments, cooling is essential for uptime, equipment longevity, and the secure flow of information around the clock.

Mission critical electrical services work closely with IT teams, installing monitoring tools that track environmental conditions in real time and adjust cooling dynamically based on workloads.

Liquid Cooling for High-Density Equipment

As computing grows more powerful, traditional air-based cooling struggles to keep up with high heat output. This is where liquid cooling shines. By circulating coolant directly to the hottest points, like processors in supercomputers or specialized servers, it removes heat more efficiently than air systems ever could.

Electricians play a key role in installing and maintaining pumps, piping networks, and distribution systems that make liquid cooling possible. This approach supports extreme workloads while keeping machines at stable operating conditions.

For industries like research, artificial intelligence, and advanced manufacturing, liquid cooling allows hardware to reach its full potential without the risk of thermal damage.

Ventilation Systems in Industrial Settings

Industrial environments pose unique cooling challenges because of both technology and machinery operating in the same space. Factories, warehouses, and production plants often generate high levels of heat that require powerful ventilation systems.

Electricians design and maintain fans, ducts, and airflow controls that keep both equipment and workers safe. By circulating fresh air and removing excess heat, ventilation prevents machinery from overheating while also improving air quality for employees.

roperly designed systems reduce fire risks, support energy efficiency, and allow large-scale operations to run smoothly. In industrial settings, cooling is about ensuring a safe and productive workspace overall.

Rack-Based Cooling Solutions

Rack-based cooling offers a targeted strategy for server environments where efficiency matters. Instead of cooling an entire room, these systems focus airflow directly around the racks holding equipment. Electricians configure hot aisle and cold aisle arrangements, ensuring warm exhaust air is separated from cool intake air.

This setup minimizes wasted energy and provides consistent, stable temperatures right where servers need them most.

By reducing the strain on broader cooling systems, rack-based strategies lower operational costs while improving performance. For businesses that depend heavily on server reliability, this method delivers both efficiency and protection, making it a go-to approach for modern IT infrastructure.

Energy Efficiency in Cooling Systems

Cooling technology has evolved beyond simply keeping equipment cool, now it must also be energy efficient. Modern systems include features like variable-speed fans, efficient compressors, and smart sensors that adjust output based on real-time needs.

Electricians often recommend these solutions because they reduce both energy consumption and long-term costs. For businesses, the benefits extend beyond savings; lower energy use also supports sustainability goals and reduces strain on infrastructure.

An efficient cooling system provides reliable protection for technology while operating with fewer resources, proving that high performance and eco-conscious design can go hand in hand.

Emergency Backup Cooling

For critical facilities, cooling systems must remain reliable even during a power outage. Without backup measures, equipment can overheat within minutes, risking costly failures.

Electricians often pair cooling systems with uninterruptible power supplies (UPS) or backup generators to ensure continuous operation. These setups give businesses peace of mind, knowing that sensitive technology will remain protected during unexpected events.

Hospitals, financial institutions, and data centers rely heavily on this safeguard because downtime is not an option. With emergency cooling in place, systems remain stable, preventing data loss, equipment damage, and safety hazards, even in the face of sudden disruptions.

Smart Monitoring and Controls

Cooling systems today are smarter than ever, thanks to monitoring tools and automation. Electricians now install systems with sensors that measure temperature, humidity, and airflow in real time.

These systems can alert staff to anomalies and even make automatic adjustments before problems escalate. Remote access capabilities allow IT and facility teams to monitor and manage systems from anywhere.

By predicting and preventing failures rather than simply reacting to them, smart monitoring enhances reliability and reduces costs. For businesses, this proactive approach transforms cooling into a dynamic safeguard, ensuring technology operates smoothly with minimal human intervention.

Specialized Cooling for Medical Equipment

Medical technology demands specialized cooling solutions to maintain precise conditions. Equipment like MRI machines, CT scanners, and diagnostic tools generates significant heat during operation, and any disruption could directly impact patient care.

Electricians working in healthcare environments design cooling systems that comply with strict safety codes while ensuring continuous operation. These systems regulate not only temperature but also humidity and air circulation to meet equipment requirements.

Reliability here is about safeguarding lives. Specialized cooling ensures medical devices stay functional around the clock, supporting accurate diagnoses and treatments without interruption.

Cooling for Renewable Energy Systems

Even renewable energy technologies require reliable cooling to function efficiently. Solar panels and inverters, wind turbine components, and battery storage systems all produce heat during operation. Without proper cooling, efficiency drops and equipment lifespan shortens.

Electricians design solutions that withstand outdoor environments, where these systems often operate under harsh conditions. Whether through active cooling systems or passive designs like natural airflow, keeping components stable ensures steady energy production.

By protecting renewable infrastructure, cooling supports the broader mission of sustainability and energy independence, helping these systems deliver reliable, clean power for the long term.

Collaboration Between Electricians and IT Teams

Effective cooling systems are rarely a one-team job. Electricians and IT specialists often collaborate to design and maintain setups that align with both infrastructure and equipment needs. They also come together for scheduled inspections which are crucial.

IT teams provide insight into hardware requirements, while electricians translate those into practical, code-compliant cooling solutions. This partnership ensures strategies are efficient, scalable, and suited for long-term use.

By bridging the gap between technical performance and operational safety, collaboration reduces risks and creates systems that adapt to changing workloads. When both sides work together, cooling becomes not just functional but optimized for business success.

Cooling Systems and Safety Standards

All cooling installations must meet strict safety codes and regulations.

Meeting these standards protects both the technology and the people working around it, preventing hazards like electrical faults, fires, or air quality issues. Adhering to safety codes also shields businesses from liability concerns, ensuring that operations remain legally sound.

More importantly, it reinforces reliability and trust, showing employees and stakeholders that systems are built to perform safely, consistently, and responsibly.

Final Thoughts

Behind every piece of advanced technology lies a cooling system working quietly to keep it running. Cooling not only preserves the performance of machines but also protects investments, saves energy, and ensures safety.

![]()